(Cantieri Riuniti dell’Adriatico – C.R.D.A.)

- Argonauta Class

- Sirena Class

- Perla Class

- Adua Class (also known as ‘Africani”)

- Acciaio Class (also known as “Metalli”)

- Introduction

- Design and Construction

- Propulsion

- Air Systems

- Crew Quarters

- Communication, Radio, and Navigational Systems

- Periscope

- Controls

- Weapons

Introduction

To understand the genesis of the “600” series, one has to look back at the pre-war disarmament conferences of Washington and London. The Conference of Washington of 1921 succeeded in curtailing the unlimited growth of the surface fleets of the major naval powers, but failed to regulate submarine warfare. This failure was to be remedied by the Conference of London of 1930, but the various naval powers were only able to define a fictitious categorization between “costal” submarines and “oceanic” ones. The first would be limited to 600 t., while the seconds could not exceed 2,000 t.

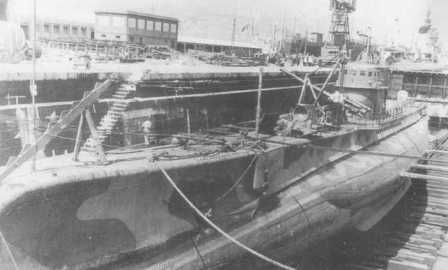

R.Smg. ALAGI

Class 600, series ADUA

Build by C.R.D.A. of Monfalcone in 1936

Eventually, the Germans demonstrated that smaller submarines could be successfully used in the oceans, and most navies understood that large submarines were of very limited use. The “600” class was Italy’s response to these new regulations which would allow naval power to build an unlimited number of “costal” submarines, vessels well suited for the Mediterranean. Two officers of the Regia Marina’s “Genio Navale” (engineering) generated the most popular submarine designs in use by the Italian Navy’s submarine fleet: Cavallini and Bernardis. The latter had been designing submarines since the First World War and was called to provide for the design for a new costal submarine class, the “Squalo”, from which one may say evolved the “600” class.

The submarine ALAGI in a dry-dock in Messina (Sicily) in 1941.

The picture shows the graceful design of the external hull.

(Photo courtesy Erminio Bagnasco and Achille Rastelli)

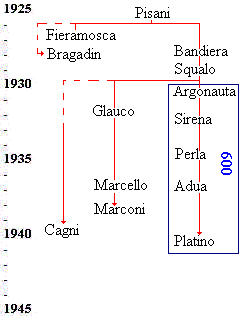

The “600” were the most numerous (59 units) of the many Italian submarines produced, and probably one of the most successful series ever built. They were produced in 5 series, which do not differ too much, but which show a slow progressive evolution of the boat within the constrained imposed upon the Italian shipbuilding industry by the war. The five series were named “Argonauta” (named after the first boat of the series), “Sirena”, “Perla”, “Adua”, and finally the “Platino”. These boats were built by various shipyards and differ only in relatively small details. The second series, the “Sirena”, began construction even before the first one was completed and operationally tested. The gamble paid off because these boats were actually of very good quality.

The evolution of the Bernardis design

Note: The series “Platino” is also known as “Acciaio” or “Metalli” (metals). The series “Adua” is also referred to as “Africani” (Africans).

The series “Adua” includes three boats built for Brazil, “Tupy”, “Tamoyo”, and “Tymbira”

Design and Construction

Since the creation of the first submarines, and not until the introduction of more revolutionary designs later in WW II and in the post-war period, submarines were made up of three distinct components: inner hull, outer hull, and superstructure.

The inner hull, also known as the pressure hull, was usually built of various cylindrical sections sealed at both ends by semispherical cups from which protruded the torpedo tubes. A second cylindrical area was positioned amidships and was enclosed in the conning tower. The outer hull was the seaworthy external shape of the submarine designed for navigational qualities. Within this outer shell there were compartments utilized for the storage of fluids (ballast or oil), external ballast or compensation tanks, and very little unutilized space. In the case of the “600” class, most tanks were enclosed within the primary structure of the boat.

The superstructure was constructed on top, aft and forward of the hulls and giving the submarine a flat deck, a cruiser-like bow and a round stern. This part was usually completely open to the ocean and seawater drained through wide openings above the outer hull, or smaller cutouts placed along the whole profile. In the case of the “600” class, the utilization of holes versus an continuous opening indicated the origin of the boat since different shipyard used slightly different design.

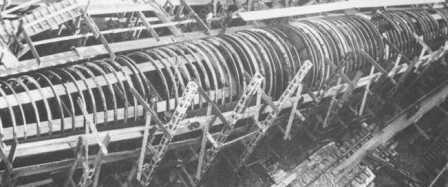

All the “600” class submarines were of the “Bernardis” type with a cylindrical pressure hull made of cylindrical beams (reinforcement rings) positioned about 520 mm (20.47 in) apart and to which were double riveted multiple steel plates positioned in a brick layer fashion (each plate tended to overlap the other half of the adjacent plates. In the final series, the “Platino”, riveting was replaced by welding. Plates were made of nickel steel with a breaking point of 60 kg/mm2 (853.4 psi), and an enervating point of 42 kg/mm2 (597.4 psi). Plates were 15 mm (0.59 in) thick around amidships and 12 mm (0.47 in) thick toward the extremity. The forward and aft sections were tapered so that the internal circumference of the supporting beams was larger in the central compartments than the extreme ones. Each plate was secured by a double row of rivets, and an extra plate was installed inside and outside of the riveted area. According to Alessandro Turrini (the foremost expert in the engineering of Italian submarines) , during testing, the hull proved to be exceptionally strong and probably built over the specifications required. In fact, during operational use, more than one boat dived well below the 80 meters (262 feet) maximum depth.

The hull was made of cylindrical beams (reinforcement rings) positioned about 520 mm (20.47 in) apart

(Photo Turrini Collection)

The entire pressure hull was divided into six primary compartments. Starting aft, the first compartment was the aft torpedo room, which also included the electric motors, followed by the diesel engine rooms, the aft battery hold and additional equipment room, the control room, the officer and petty officer quarters and forward battery holds, and finally the forward torpedo room. Above the control room there was a smaller chamber (inside the conning tower). The two periscope sleeves were also considered parts of the pressure hull.

A watertight bulkhead capable of withstanding water pressures up to 80 atmospheres (1138 psi) separated each compartment. The outer hull was made of 7 mm (0.2756 in) steel, and as already mentioned, the space in between the two hulls was used to stow diesel fuel and ballast water. The upper deck was surfaced with teak wood slats bolted to the metal frame. The “600” had a round bow; the first series, the “Argonauta” had a sharp bow which, in all later series, was replaced by a typical “shark-like” one.

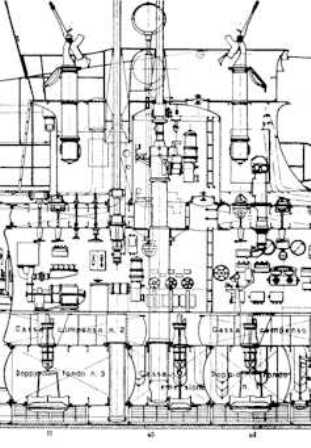

Drawings

The periscope

Propulsion

Diesel Engines

The various series of the “600” class were equipped with diesel engines similar in performances, but produced by different manufacturers. The “Argonauta” were able to develop 1,250 HP, later increased to 1,350 HP on the “Sirena”, and 1,400 HP on the “Perla”, “Adua” and “Platino”. Some of the boat of the “Platino” class received power plants capable of producing 1,500 HP. All these engines were in general two-stroke reversible and produced by FIAT, TOSI or C.R.D.A. The engines on the “Perla” had four cylinders; the “Argonauta” and the “Adua” had engines with six cylinders. The “Platino” had five. In the long run, the engines produced by C.R.D.A. appeared to be the most efficient.

The surface speed of all the “600” boats was around 14 knots, while submerged speed was 7.5 knots excluding the first series, the “Argonauta”, capable of 8 knots. Throughout the evolution of the various power plants, endurance remained somewhat similar with the boats capable of reaching 5,000 miles at 8.5 knots, and 2,300 miles at the maximum speed of 14 knots. The diesel engines were connected to the electric motors via a joint, which could be disconnected. The maximum operating RPM (revolutions per minute) was usually 420, but the engines could be pushed to 460 RPM for a limited period of time.

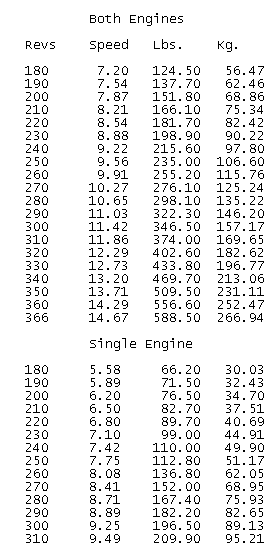

To give a general idea of fuel consumption, use this chart created by the Allied after the capture of the Smg. Bronzo

After intense use, the diesel engines were prone to failures and required extensive maintenance. The limited speed of the “600” was not a great factor, but in bad weather the engines intake valve, situated just above the engines on the deck instead of inside the conning tower as in foreign design, would easily flood.

In general, as for most Italian submarines, the surface speed of all the class “600” submarines was very limited and could not be improved with the installation of new engines. A German type VII A submarine, somewhat similar to the “600”, could reach 17 knots versus the 14 of the Italian boats.

Electric Motors

Similarly to the diesel engines, different manufacturers produced the electric motors. Some received motors produced by C.R.D.A., while others received similar units produced by Marelli and Ansaldo. These motors could operate at 45, 90 and 180 volts. The maximum output was obtained running 180 volts and 330 RPM. When not in use for propulsion, the electric motors could be used to generate D.C. (direct current) to recharge the batteries. Each motor was capable of producing up to 400 HP.

Batteries

On the “600” there were two holds capable of 52 batteries each. On the “Sirena”, each cell was of the type Ironclad N 7320 produced by the Tudor and weighed 700 kg (1543 lb) each. The total weight of all cells was 72.8 tons (80.25 short tons). The batteries could deliver 4,750 amps in one hour, 7,050 amps in three (2,350 amps/hour), and 9,720 amps in twenty hours (485 amps/hour). On the first series, the “Argonauta”, each battery was capable of producing only 4,270 Ampere/Hour. When captured, the Smg. Bronzo was equipped with batteries produced by Marelli of Milan of the type Quaroldo M.51. These batteries had been installed in September 1941, and at the time of the boat’s capture, they were in perfect conditions, thus confirming that their operational life was relatively long.

Each cell was made of multiple positive and negative plates made of lead, each with common terminals, separated by insulators. The plates were immersed in an electrolyte solution made of pure water (distilled water) and pure sulfuric acid with a specific gravity of around 1.25 when fully charged. Each cell produced approximately two volts and was permanently wired in series. Each of the two battery groups could be operated independently or in parallel. On the “600” each battery group was divided into two busses, each composed of 26 cells (26 x 2 volts = 52 volts).

Air Systems

The compressed air system was one of the most important systems on the submarine. It was used to blow the ballast tanks, fire torpedoes, and to start the main engines. Without a functional air system the submarine became inoperable. Docking facilities were usually provided with the necessary high-pressure air supply so that the submarine would not have to produce its own. Air tanks tended to accumulate condensed moisture (water), thus they were regularly drained for maintenance. On the “600” class the primary air compressor was installed in the auxiliary room. It was build by San Giorgio and capable of pressurizing air up to 200 kg.cm2 (2845 psi) and producing 9 liters per minute (0.31 cubic feet per minute). The compressor was powered by an electric motor.

There were also two super compressors capable of boosting air pressure to 200 kg.cm2 (2845psi). They were driven by the main diesel engines. This system received air from the two compressors built into the diesel engines and air was stored into tanks with a total capacity of 8,020 liters (282.5 ft3). These compressors could only be used when the submarine had at least the conning tower out of the water so that the hatch could be open to supply external air.

The air was stored in six groups of tanks, two located in the forward torpedo room, two in the auxiliary room, and two in the engine room. The tanks in the engine room were more numerous than the ones in the forward torpedo room, and the auxiliary room had the least number.

Air Filtering System

The “600” were equipped with an air filtration system for the removal of CO2 (Carbon Monoxide). There were also 10 oxygen tanks used to oxygenate the depleted air while submerged. The submarine was equipped with external hookups so that, in case of malfunction, a support ship could blow the ballast tank and also provide breathable air. Due to primitive nature of the air circulation system, when submerged, the crew would experience very uncomfortable conditions and the air was reportedly foul within a very few minutes.

Crew Quarters

On the “600”, the officer quarters were located just forward of the control room and past the R.T. and hydrophone rooms. The non commissioned officers shared the space in the forward torpedo room, while the rest of the crew would use the bunks in the aft torpedo rooms.

Galley

There were two galleys, one powered by electricity and located in the forward torpedo room, and one burning diesel oil and located within the conning tower. Eventually, the galley located in the conning tower was found unpractical and the last series, the “Platino”, had it removed. Meals at sea were very simple, and cooking underwater was discouraged due to the generation of water vapors which would eventually create further condensation.

Heads

There were three heads inside the submarine, one located in the forward torpedo room next to the galley, one in the auxiliary equipment room, and one reserved for the officers.

Fresh Water

The submarine had a small reserve of fresh water.

Refrigeration

There was a small refrigeration system located in the auxiliary equipment room, quite far from the galley, which was located in the forward torpedo room. Non-perishable food was instead stowed in a small hold situated in the forward torpedo room.

Crew

The “600” had a crew of 4 officers, 10 non commissioned officers and 22 enlisted men. The four officers were the commanding officer, usually a T.V., his second the chief engineer and another engineer.

Safety Systems

Between the torpedo rooms and the internal compartments, the engineers had placed two Gerolami-Arata lifts. These devices consisted of a sealed chamber which would float to the surface by buoyancy and could then be retrieved by a tether connected to the bottom of it and secured to a winch. Each time the chamber was released it could take one crewmember to the surface without incurring any of the dangers caused by exposing the human body to the high water pressure of the depths.

The Gerolami-Arata escape system

Due to the presence of this device, the bulkhead between the torpedo rooms and the inner compartments was equipped with two hatches. There were also external hook ups to connect a sunken boat to external air and water lines. Also, each boat had two floating buoys installed above each torpedo room and which could be released to the surface. Each buoy was equipped with a telephone system and devices to have them easily located.

he radio room was installed between the officer quarters and the control room. The “600” were equipped with a radio localizer apparatus mounted on the conning tower and controlled from the radio room.

General announcing system

All “600”were equipped with an announcing system. Each compartment could communicate with a central station located in the control room via a speaker microphone system.

Alarm system

The “600”were equipped with a klaxon operated from the control room. Upon sounding the alarm, all hatches would be secured and the engineers would commence the diving procedures securing the diesel engines’ intake and exhaust valves.

Telephone call system

The “600”were equipped with two buoys situated on deck and attached to a retrieval system. If necessary, the buoys could be released and floated to the surface, giving surface units a telephone connection to the submarine.

Hydrophones

There was a hydrophone system connected to two external transmitters. The system was of domestic production and considered effective.

Gyrocompass

The “600” class was equipped with a gyrocompass of the type Anschutz installed in auxiliary room which had three repeaters installed in various compartments (and also in the wheelhouse). There was also a magnetic compass installed in a water-proof casing on deck with a repeating station in the control room.

The gyrocompass received its directive from a high-speed spinning gyroscope driven by electric motors. Its directive action is based on the mechanical laws governing the dynamics of rotating bodies. When any object is spinning rapidly it tends to keep its axis pointed in the same direction. The gyrocompass consists of a spinning gyroscope, made north seeking by placing a weight below the axis, which is mounted in gimbals so that the movements of the submarine do not effect its position.

A dial mechanically connected to the gyrocompass has the points of the mariner’s compass marked on it and indicates the submarine’s true course. The gyroscope required some time before becoming operational, thus it had to be started in advance of leaving port.

Periscope

There were two periscopes. The forward one, used to attack, was produces by Zeiss, while the aft one, used for exploration, was produced by the firm Galilei. On the “Perla” the Zeiss was replaced by a new model produced by San Giorgio.

Typical of Italian submarines, the periscope sleeves extended considerably from the conning tower and were enclosed in a light metal structure quite visible from a distance. On the last series, the “Platino”, the periscopes reflected the German style conning tower and were completely recessed. The exploration periscope was accessed from the control room and its well went down all the way to the keel. The attack periscope, used at lower depth than the exploration one, could be accessed from small chamber in the conning tower.

Controls

When the “600”were on the surface, they operated like any other boat demonstrating good seaworthiness. Maintaining the various ballast tanks full of air provided buoyancy.

Rudder

The rudder (semi-compensated) was controlled electrically from the control room, or manually for the aft torpedo room. Also, there was a wheel in the conning tower in an enclosed wheelhouse. On the “600” the rudder had a total surface of 5.24 m2.

Diving Planes

As standard on most submarines, the “600” were equipped with two sets of diving planes. The forward planes were collapsible (folded upward) for surface navigation and were placed above the waterline; their total surface was 4.97 m2.

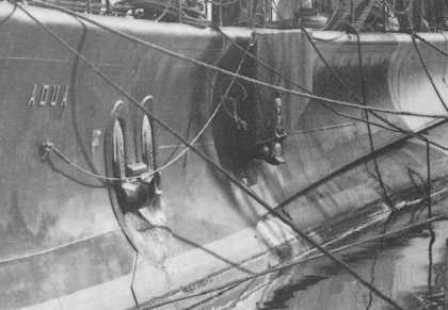

The forward diving plane and the anchor of the submarine Adua.

(Photo Turrini Collection)

The aft planes were fixed and placed below the waterline in line with the two propellers and their surface was 3.78 m2. The forward planes were used to control depth, while the aft ones were used to control the angle of the boat. The planes were controlled electrically from the control room, but could also be manually operated from the torpedo rooms.

Anchors

The “600” were equipped with a primary anchor, installed on the port side, and the chain was stored in a well located below the forward torpedo room.

Weapons

Torpedoes

All “600”excluding some of the latest “Platino” were fitted with two torpedo tubes aft and four forward. The Bronzo, Volfamio and Argento had four aft tubes. All tubes were loaded before leaving port and six extra torpedoes were stowed aboard giving the “600” a total of 12 torpedoes, while the latest series had 8 or 10. Torpedoes were loaded through a special hatch and the operation was very laborious. Once at sea, torpedoes could be removed from the tubes for limited maintenance (fuel topping).

Range, speed and direction of the weapons could be configured while they were inserted in the tubes. The tubes, produced by Tosi of Taranto (and probably other manufacturers), could take a variety of 21’ (533 mm) torpedoes produced both by Whitehead and “Silurificio Italiano”. Similar to the Royal Navy, the Regia Marina did not experience the kind of massive torpedo failure which plagued the U.S. Navy and the Kriegsmarine. Italian weapons were reliable, but left a visible trail thus making them easy to spot. Only the last series, the “Platino”, received a German made launch control system. Toward the end of the war (1943), the “600” received electric torpedoes from the Germans which proved quite effective.

Smaller Weapons

Each boat was equipped with a small armory containing rifles and side arms and located in the hydrophone room.

Deck Guns

The first “600” series was fitted with a 4” (102) mm deck gun caliber 35. These guns had a maximum range of 15,000 meters, but the practical range, due to the simplicity of the optical range finder, was much lower. Later classes were fitted with the newer 100 mm caliber 47, The “600”carried from 152 to 144 shells. A well-trained gunnery team could fire eight shells per minute.

The 100/47 mm deck gun of the Smg. PORFIDO.

(Photo Turrini Collection)

The “600” had a single gun mounted forward of the conning tower. Shells were loaded from the stowage area below onto the main compartment and from there pushed up to the deck through a tube. Since there are no specifications for a mechanical or hydraulic hoisting system, it is assumed that the shells were pushed by hand. The gunners also had access to a ready storage area built into the conning tower and secured by a watertight hatch. The ammunition stowage was located on the lower deck between the forward battery hold and the quick dive tank. Due to the nature of the conflict in the Mediterranean, the deck gun of the “600” was of very limited use.

Machine Guns

All “600”were equipped with the famous Breda Model 1931 13.2 mm anti-aircraft machine gun. These guns were mounted on a single support on the early series and on double mounts on later ones. On the “Platino”, probably one of the best Italian submarines ever built, the guns were installed on a retractable mount, which would recede into a water-tight tube protected by a small hatch. Upon emerging, the gunners had to simply release the hatch, lift the guns out of the enclosure, and install the clip and fire. Each clip contained 30 rounds and the gun could fire up to 400 rounds per minute at a range of 2,000 meters. The “Argonauta” had a reserve of 6,000 rounds, later increased to 10,000. As with all Italian submarines, toward the end of the conflict it was discovered that the 13.2 mm guns were insufficient in downing large American bombers protected by a thick armor.

Other Weapons

In August 1940, units of the ADUA series underwent important structural modifications for the installation of cylindrical containers for the transport of sub-attack crafts S.L.C. (Siluro a Lenta Corsa), the famous “maiale” .

Later, the conning tower was modified similarly to the German U-Boots, removing the highly visible enclosed deck and lowering the periscopes’ sleeves. The 100/47 gun was removed and a new A.A. machine gun added. The units were fitted with three cylinders, one forward and two aft. Each cylinder could carry a single S.L.C. The Scirè and the Gondar were almost identical, but the forward cylinder of the latter did not have reinforcement rings thus allowing for the two units to be properly identified. Despite her notoriety, there actually are very few pictures of the Scirè, and of the few, many were manually retouched.