The Balilla class, consisting of four units dedicated to as many patriots, was the first class of submarines to be built in Italy after the end of World War I, after a “pause” of a few years due to the difficult Italian economic situation after the conflict. In the first half of the 1920s, with the gradual improvement of the Italian economy, the Regia Marina decided to launch a plan to renew the submarine fleet, starting with the construction of a class of large displacement submarines capable of operating outside the Mediterranean for long periods. The intent was to carry out an offensive against enemy traffic even in faraway oceans controlled by the adversary (according to some sources, the Balilla were designed for the war against traffic in the Indian Ocean, departing from Italian bases in East Africa).

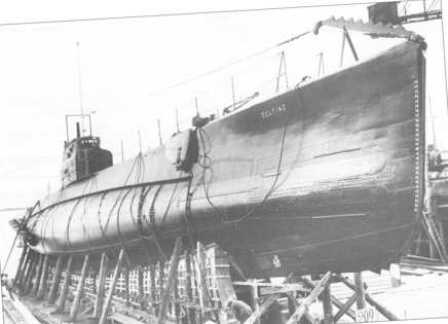

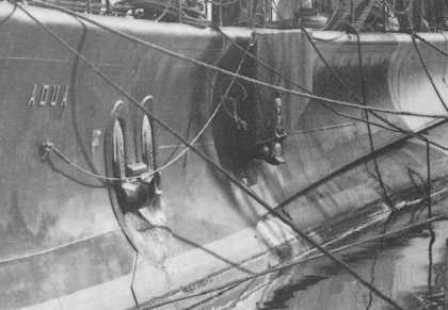

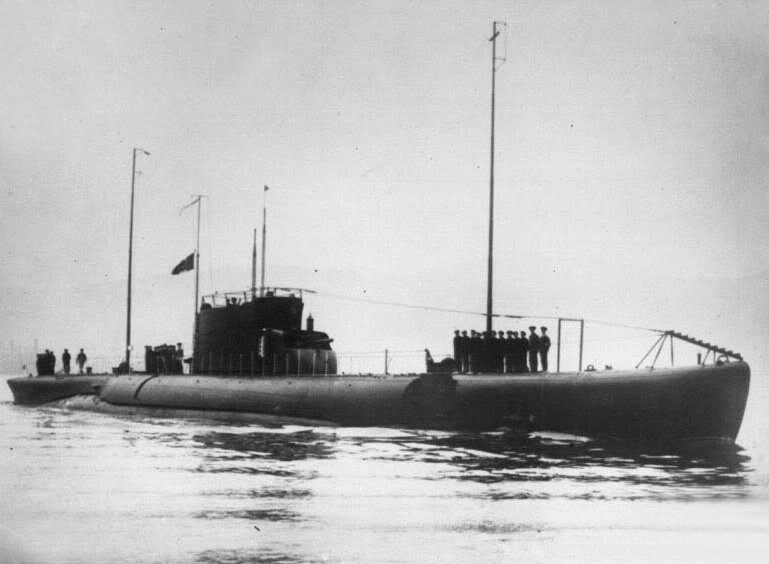

Balilla in the early years of service with the radio masts raised

Thus was born the Balilla class, whose construction was ordered with the 1923-1924 naval budget (the first in which the Navy began to receive the necessary funding for the renewal of the fleet after the end of the Great War) and entrusted to the Ansaldo San Giorgio del Muggiano shipyards, which in 1925, the year of their establishment (for another source, in 1927), changed their name to Odero Terni Orlando.

Grand Admiral Paolo Thaon di Revel, appointed Minister of the Navy on October 31st, 1922, had decided that the renewal of the submarine fleet should begin with the construction of “prototypes” of new classes of submarines, some of which should also be able to operate in the oceans. At the end of 1922, the development of the design of these prototypes was entrusted to the ‘Ship Design Committee’, and then passed to other boards. A board composed of the Deputy Chief of Staff of the Navy, the directors general of the Ministry of the Navy, the head of the Submarine Department of the General Staff and the commander of the Submarine Squadron of La Spezia was charged with studying whether it would be more convenient to build four large cruise submarines or five medium cruise submarines; the decision, unanimously, was for the first option, according to the reasoning that such boats, being also usable in the oceans, would be useful in the event of war against certain countries, starting with France.

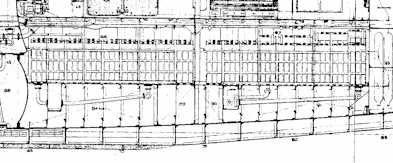

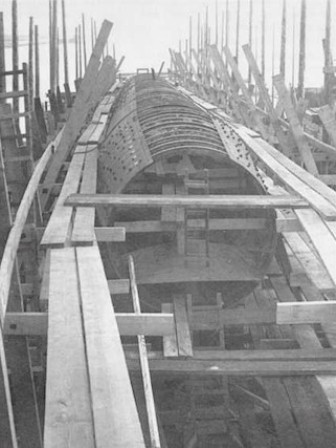

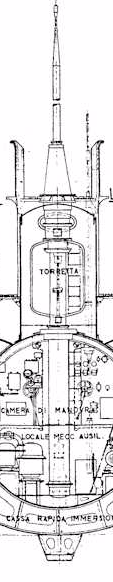

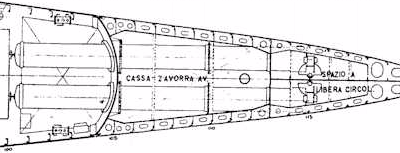

The General Staff of the Navy established some fundamental characteristics that the new boats should have such as: operational depth of 100 meters, torpedo armament of the caliber of 533 mm, artillery armament with both anti-ship and anti-aircraft functions, speeds of 17 knots on the surface and 8 knots submerged. Inspired by the German “submarine cruisers” of the Great War, the Balilla belonged to the “double total hull” type with an internal hull, tested to withstand a depth of 100 meters, formed by a cylindrical spindle that formed two truncated cones at the ends, with the emergence, rapid and trim boxes and lubricant tanks inside, and an outer hull, formed by a lightweight structure which included the floodable compartments (which surrounded most of the resistant hull) and the open spaces. The fuel was partly contained in the inner hull and partly in the double bottoms. Developed privately by the Ansaldo San Giorgio shipyards in collaboration with the technical departments of two other large shipbuilding companies, the Odero Terni Orlando and the Cantieri Riuniti dell’Adriatico, the total double hull would become one of the three main types of submarines built for the Regia Marina in the interwar period, together with the “single hull with counterhulls and double external bottoms” type designed by Colonel Curio Bernardis of the Naval Engineers and the “double hull” type partial hull” designed by Lieutenant Colonel Virginio Cavallini of the Naval Engineers.

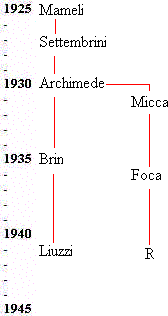

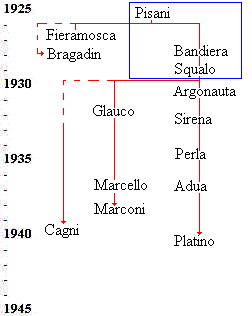

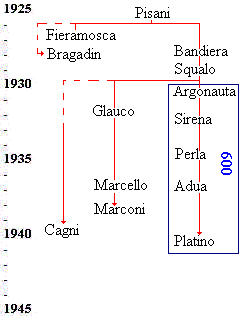

With a displacement of 1,464 tons (some sources indicate 1,450) on the surface and 1,927 (other sources indicate 1,904) submerged and an overall length of 86.75 meters, the Balilla were the largest submarines ever built in Italy, and even later they were surpassed in size by very few classes. Those were, among the “attack” ocean submarines, the unsuccessful Ettore Fieramosca of 1931, 1,556/1,965 tons, the three Calvi class 1,550/2,060 tons in 1935 and the four Admirals class 1941, with a displacement of 1,702/2,184 tons. In addition, the large minelaying submarine Pietro Micca of 1,567/1,967 tons of 1935 and the transport submarines class R, of 2,210/2,606 tons, completed starting from 1943.

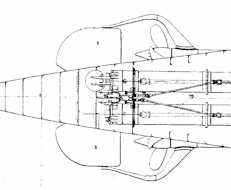

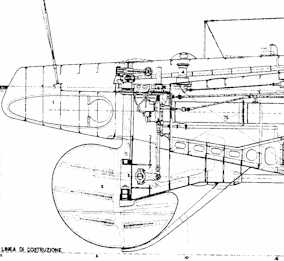

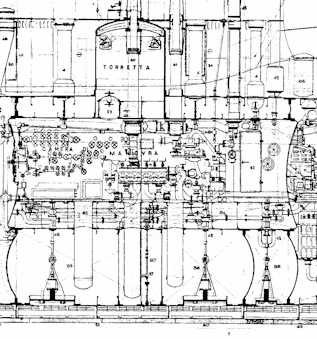

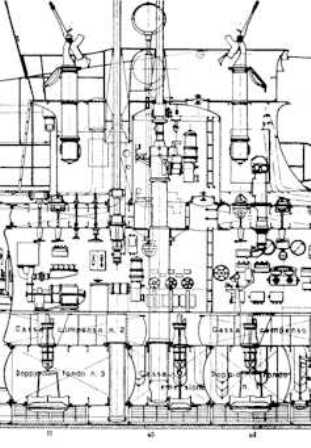

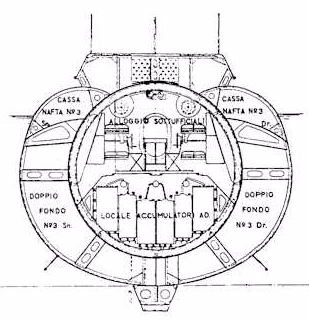

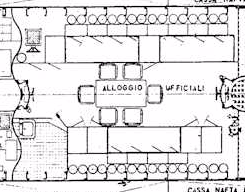

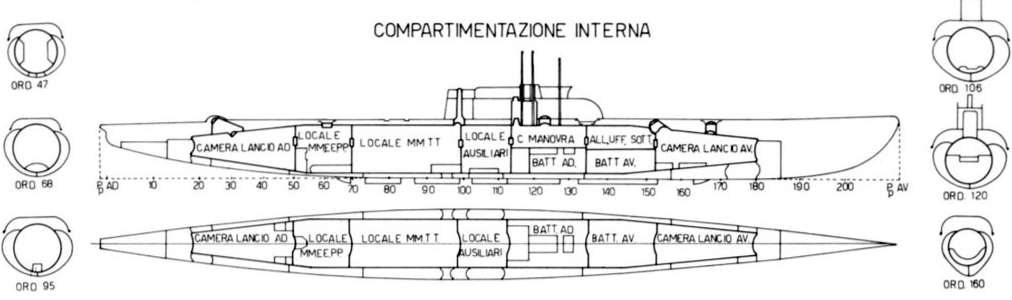

Internal layout

The submarine Balilla belonged fully to the category of “cruiser submarines” of large size and great autonomy (the first Italian units of this kind: they were, in fact, the first real ocean-going submarines of the Regia Marina), designed for the war against merchant traffic in distant seas, with long missions that would have taken them a great distance from their bases of departure. Their design, developed in 1923 by the Ansaldo-San Giorgio company, had been influenced by that of the German UE II class (displacement of 1,164 miles on the surface and 1,512 submerged, range of 11,470 miles at 8 knots), one of which, the U 120, had been delivered to Italy in November 1918. Given their intended use, great importance was given to autonomy, nautical qualities, and habitability in their design.

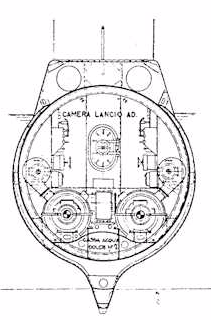

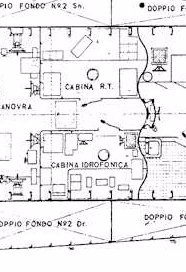

The resistant hull of the Balilla was divided into seven watertight compartments. From bow to stern they were: forward torpedo launch chamber, officers’ and non-commissioned officers’ saloon and bow battery room, control chamber and stern battery, auxiliary engine room, diesel engine room, electric propulsion engine room, aft torpedo launch chamber. A total of 456 tons of water could be loaded into the ballast tanks. Compressed air for the tank of the ‘rapid’ was stored in containers with a total capacity of 11,900 litres, and its use had to be limited to emergency cases only, as the recharging of the compressed air, carried out with San Giorgio electric compressors, required a long period on the surface.

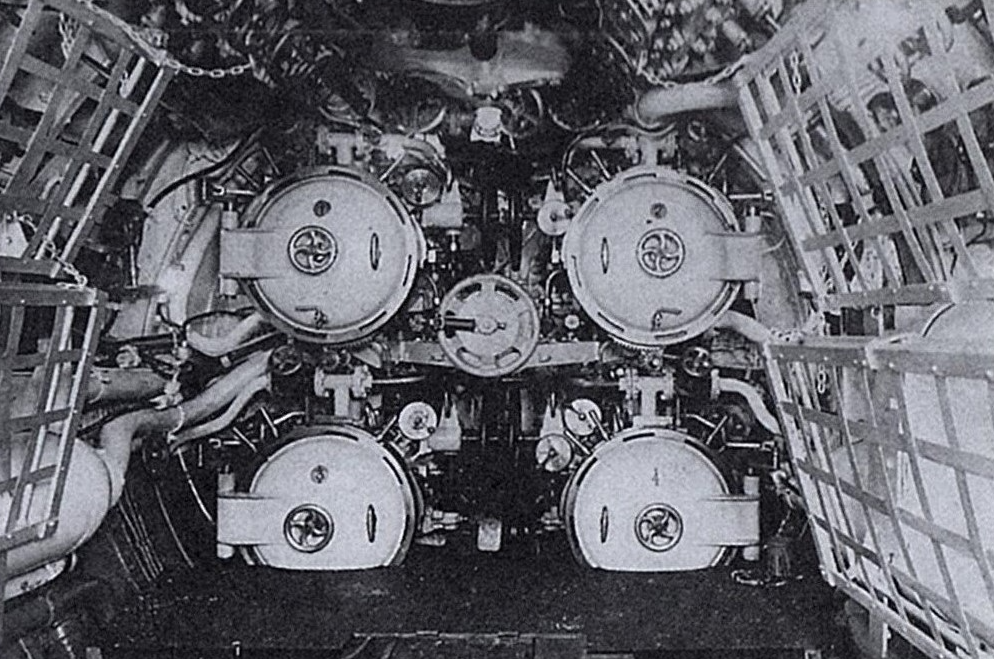

The forward torpedo room

The steering rudder had an area of 7.4 square meters. The forward planes, located above the waterline, were foldable, while the aft ones were located just aft of the propellers. The planes were electrically operated from the control chamber, but in case of emergency they could also be operated manually from the forward torpedo launch chamber (for bow depth planes) or from the aft torpedo launch chamber (for stern planes).

Officers and non-commissioned officers were accommodated in two adjacent cabins, located above the forward battery room. Sailors slept in bunk bunks in the two launch chambers.

The supply of fresh water, stored in three tanks, was 12 cubic meters. If necessary, an additional eleven cubic metres could be stowed in the compensation boxes. There was also an electric distiller on board capable of producing 2,000 litres of fresh water per day. For fresh food there was a cold room of the Audiffen Singrun type. There were two galleys, an electric one located in the forward launch chamber, and a diesel one, usable only in surfacing, inside the conning tower.

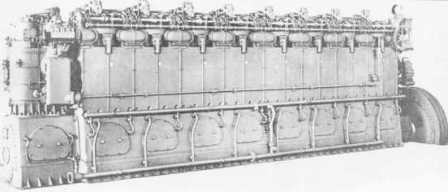

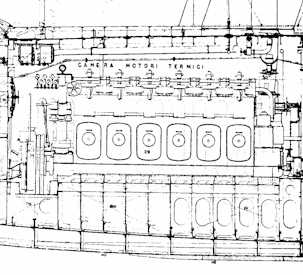

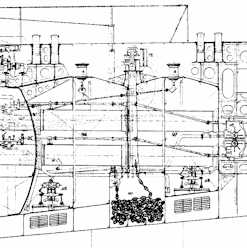

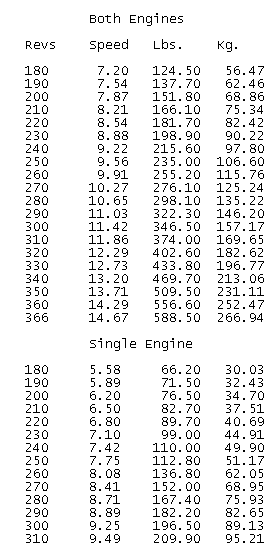

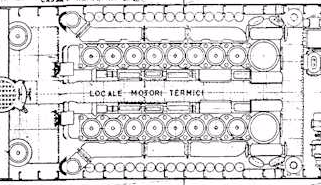

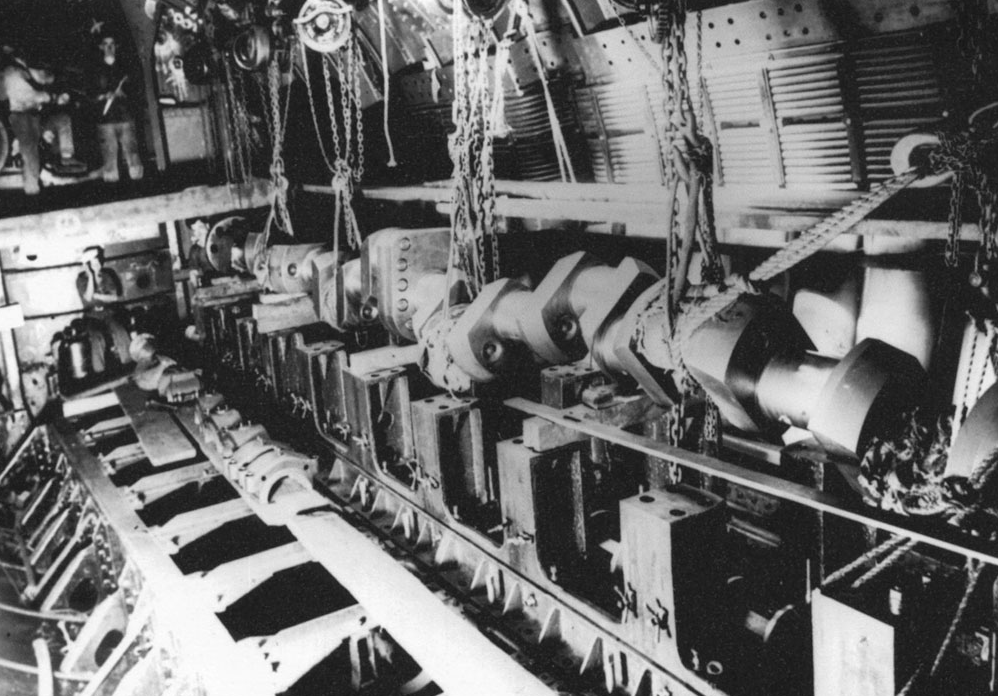

The propulsion system for surface navigation consisted of two FIAT Q 458 two-stroke diesel engines with a total power of 4,900 hp (2,450 hp per engine; for another source 4,000 hp in total, 2,944 kW), at 380 rpm, which allowed a maximum speed of 17.5 knots. The one for submerged navigation was represented by two Savigliano direct current electric motors with a total power of 2,200 hp (1,620 kW in total; 1,100 hp for the engine at 280 rpm for one hour, or 600 for the engine at 230 rpm for 3 hours), with a maximum speed of 8.9 knots. There were two, three-bladed propellers.

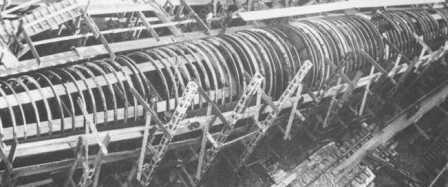

Installation of one of the main engine shafts

(According to another source, however, the speeds of 17.5 knots on the surface and 8.9 in submerged were the maximum speeds envisaged by the project, while the actual ones were slightly lower: 16 knots on the surface – 17.5 knots were reached only in the tests – and 7 submerged).

With a supply of 152 tons of diesel, the surface range was 3,000 miles at 16 (or 17) knots, 7,050 at 8.5 knots and 12,000 (or 13,000) at 7 knots. Submerged range was 110 miles at 3 knots, 80 miles at 4 knots and 8 miles at 8.9 knots. The electric motors were powered by a bank of lead-acid batteries, consisting of 240 elements divided into four groups of 60. Each accumulator could generate 3,200 ampere-hours for one hour, or 6,300 ampere-hours for 10 hours.

There was also an auxiliary engine (consisting of a FIAT Q 304 diesel generator, derived, according to one source, from the German MAN diesel engines of the Great War) with 425 or 500 hp (368 kW) and 500 rpm for surface navigation (it supplied energy to the two main electric motors and it was also used to charge the batteries and to supply electricity for auxiliary services), with which it was possible to reach a maximum speed of 7 knots and a range, at this speed, of 12,000 miles.

The testing depth was 100 meters (110 for another source; during the tests the Millelire reached 122 or 135 meters), considerable for the twenties.

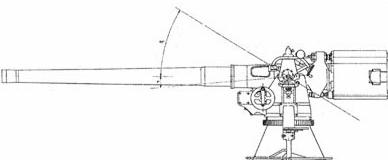

The armament originally consisted of a 120/27 mm OTO Mod. 1924 (with a reserve of 150 rounds), placed in an unusual shielded housing forward of the conning tower (of which this housing was a continuation, forming a single block with it), and two single 13.2/76 mm machine guns (with a reserve of 3,000 rounds per machine gun) and six 533 mm torpedo tubes, four at the bow and two at the stern, with 12 torpedoes (eight for the bow tubes and four for the stern ones; another source speaks of a total of 16 torpedoes, two for each bow tube and one for each stern tube). There was also, at the aft end of the resistant hull, a horizontal mine tube with which it was possible to transport and lay four mines from inside the submarine. However, this tube was eliminated on all the units of the class, with the exception of the Balilla, during works carried out in the mid-thirties, in which the structures of the extreme stern were also modified (another source states that the mine launcher tube was installed only on the Sciesa, other sources indicate that Sciesa was the only one of this class that never had it).

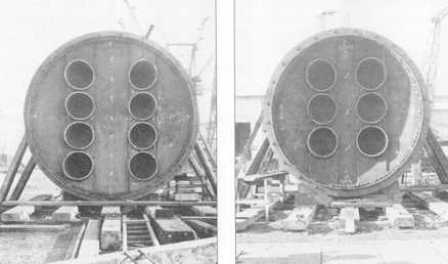

Construction of the resistant part of the hull

In 1934 the armament was modified, removing the 120/27 gun, and replacing it with a more modern (and long) 120/45 mm OTO Mod. 1931, installed in a more traditional “unprotected” arrangement on deck, forward of the conning tower. The two single 13.2 mm machine guns were also replaced with twin guns of the same caliber.

A special feature of the class was the periscope rangefinder, which could be raised or lowered by means of a rope lifting system, driven by an electric motor. Usable as an exploratory periscope (in addition to the two existing periscopes, attack and observation), it consisted of two distinct parts, a rangefinder and a periscope. The rangefinder was of the mono-static coincidence type. The periscope length was eight and a half meters, the base of the rangefinder was one and a half meters, and the apparatus was capable of 22 magnifications, could rise or depress by 15°, and had unlimited swing.

On the whole, the Balilla were judged to be successful submarines, robust, manoeuvrable and of good seaworthiness both on the surface and underwater (good seaworthiness, good manoeuvrability while diving), as also confirmed by the long and demanding test cruises that were made in the Atlantic (by Balilla and Millelire during the “Decennial Air Cruise” of 1933) and in tropical seas (by Toti and Sciesa which, in 1933-1934, circumnavigated Africa). Their main flaws, according to some sources (e.g. “Submarines: An Illustrated History of Their Impact” by Paul E. Fontenoy), were a not exceptional stability and a certain slowness in dive times, the latter problem common to almost all Italian submarines. The auxiliary diesel engine also proved to be too unreliable for its original function – that of making long-range missions possible – so much so that it was decided not to install it on subsequent classes of submarines, in order to save precious space inside the hull (with the exception of the Admirals class, large long-range “cruiser submarines” built during World War II, on which this concept was taken up).

A fifth submarine of the Balilla class, the Humaitá, was built by the OTO for the Brazilian Navy (whose entire submarine, from its birth in 1914 to the fifties, was made up of Italian-built units: the first submarines in Brazil were three F-class boats, built by the FIAT-San Giorgio shipyard in La Spezia; after the Humaitá they were built for Brazil, in 1937, three submarines of the Adua class, which together with the Humaitá represented the entire Brazilian submarine fleet during the World War II), which became interested in the new class while the project was still being studied.

Balilla being fitted along Millelire and Humanità

(From “Gli squali dell’Adriatico” by Alessandro Turrini)

It was a modified version of the Balilla class, with a displacement of 1,390 or 1,450 tons on the surface and 1,884 submerged; the main differences compared to the Balilla were represented by the position of the diesel engines (produced by Ansaldo, instead of FIAT) and electric engines (placed further forward), in the absence of forward depth planes, in a different distribution of the ballast boxes, in the different caliber of the deck gun (102 mm, instead of the 120 of the Balilla), in the greater capacity for transporting and laying mines (16 weapons), in the longer length of half a meter, in the slightly shallower draft (four meters, instead of 4.11) and in the slightly higher speed both on the surface (18.5 knots) and in submerged (9.5 knots). Ordered by Brazil in 1925, in addition to the four boats already laid down for the Italian Navy, it entered service in July 1929, the Humaitá would be decommissioned in the early fifties.

From the Balilla class was derived the design of the Calvi class of ocean-going submarines, built in three specimens in 1932-1935, which gave excellent results during the war. Elements of the Balilla design, starting with the total double hull structure, were also taken up in the design of the smaller medium-cruising submarines of the Argo class, which was also judged to be very successful and then reproduced and improved with the Flutto or Tritone class.

The Soviet Navy, which in 1925 obtained from Italy, through a naval mission, a copy of the Balilla class designs, incorporated various elements into the design of the (not very successful) Dekabrist class (six units built between 1927 and 1930), the first submarines built in the Soviet Union after the October Revolution.

In the course of their operational life, the submarine of the Balilla class received various improvements, on the basis of the experiences acquired. After the first years of service, however, their efficiency declined due to the rapid deterioration of the material (especially of the engine systems, subject to frequent failures), and at the outbreak of World War II, with already twelve years of intense service (including ocean cruises and participation in the Spanish Civil War) on their shoulders, they were worn out boats of reduced efficiency, which required long periods of work after each mission, even of short duration (their large size, moreover, made them unsuitable for use in the Mediterranean). After a few offensive missions, they were therefore assigned to training tasks or transport missions. Three of them were disarmed during the war and transformed into barges or pontoons (Balilla and Millelire already in 1941, Toti in 1943), the fourth (Sciesa) was lost at the end of 1942 during a transport mission. The historian Giorgio Giorgerini gives the following assessment: “… They were judged to be of excellent nautical qualities and excellent underwater maneuverability, qualities that were also demonstrated in the long cruises carried out by these submarines in distant warm and cold seas. A few deficiencies were recorded when they entered service, but this is quite normal when building units that in practice are still prototypes. They were a good testing ground for later boats, but by the time they entered the war in 1940 they were naturally outdated and old.”