- Introduction

- Design and Construction

- Propulsion

- Air Systems

- Crew Quarters

- Communication, Radio, and Navigational Systems

- Periscope

- Controls

- Weapons

Introduction

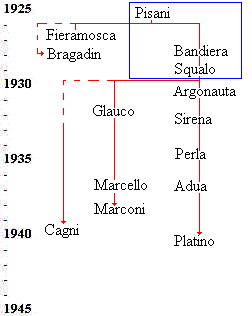

Two officers of the Regia Marina’s “Genio Navale” (engineering) generated the most popular submarine designs in use by the Italian Navy’s submarine fleet: Cavallini and Bernardis. The “Bernardis” were produced in several classes and they all evolved from the “Vector Pisani Class”, built starting in 1925. Three years later came the “Bandiera Class” and two years later, in 1930, the almost identical “Squalo Class”. Later evolutions, namely the “Glauco Class” in 1932, the “Marcello Class” in 1937”, and the “Marconi Class” in 1939, made the Bernardis true oceanic submarines and they are covered in a different section of this site.

The evolution of the early Bernardis

Colonel Curio Bernardis, later General, began the design of a new class of submarines merging the previous design by Laurenti with new, and quite innovative ideas. The goal was to create boats capable of reaching greater depths relying more on the structural integrity of the external part of the resistant hull, rather than the thickness of the internal beans. Bernardis’ design called for a traditional circular hull enclosed at both ends by a semispherical cup. Whiel the ballast tanks were positioned at the end of the resistant hull, inside this there was an additional tank which allowed for high dept operations since it could be emptied both utilizing compressed air and pumps.

The Vector Pisani

(Photo Turrini)

The original Bernardis were not very successful, but their evolution gave birth to the Marcello and Marconi classes, some of the most successful products of the Italian submarine shipbuilding effort. The Vector Pisani Class included four boats built between 1925 and 1929, and as soon as they underwent testing at sea a serious flaw was immediately discovered: the boat tended to roll quite heavily. To overcome this serious deficiency, the shipyard added some small saddle tanks which, while partially solving the problem, caused the surface speed to drop from 17 to 15 knots, and the submerged one from 10 to 8. To improve stability, some of the equipment was rearranged within the delicate balance allowed by submarine construction.

Mameli

Pisani

Squalo

Eventually, these saddle tanks were integrated in the project and become part of the Bernardis design. Unfortunately, while the problem was still undergoing studying on the Pisani, the Bandiera were already in advanced state of completion, thus they also had to be retrofitted. Furthermore, on the Bandiera another problem had to be corrected, the boat tendency to dip down by the bow. This problem was resolved by installing a special auto-filling tank which, while the unit was on the surface, would stay empty and give extra buoyancy, while in immersion would fill itself up. Further modifications to the Bardiera gave this class the unique bow which earned the four boats the nickname of “big nose”, or “nasone”. Unfortunately, even the third evolution of this series of submarines, the “Squalo Class”, was laid down too soon and they had to be heavily modified. Eventually, the first 12 boat of the Bernardis type laid the foundations for future design, first the 2 “Glauco” and then the 11 Marcello and 6 Marconi.

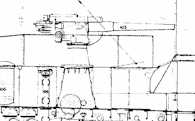

Design and Construction

Since the creation of the first submarines, and not until the introduction of more revolutionary designs later in WW II and in the post-war period, submarines were made up of three distinct components: inner hull, outer hull, and superstructure. The inner hull, also known as the pressure hull, was usually built of various cylindrical sections sealed at both ends by semispherical cups from which protruded the torpedo tubes. A second cylindrical area was positioned amidships and was enclosed in the conning tower. The outer hull was the seaworthy external shape of the submarine designed for navigational qualities. Within this outer shell there were compartments utilized for the storage of fluids (ballast or oil), external ballast or compensation tanks, and very little unutilized space.

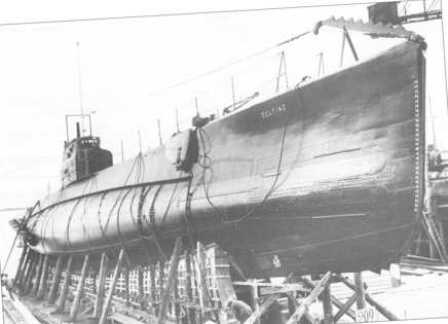

The DELFINO still on the slip and without the saddle tanks.

(Photo Turrini)

The superstructure was constructed on top, aft and forward of the hulls and giving the submarine a flat deck, a cruiser-like bow and a round stern. This part was usually completely open to the ocean and seawater drained through wide openings above the outer hull, or smaller cutouts placed along the whole profile. The “Pisani” class, as already mentioned, had the shape of the hull modified with the additional of small saddle tanks, thus improving the navigational qualities of the vessel. Due to these alterations, the speed of the first three classes (Pisani, Bandiera and Squalo) would be limited to only 15 knots, while later classes would reach 17 and 18 knots.

All the “Bernardis” class submarines were of the simple hull design with double internal ballast tank. The Pisani Class had a perfectly cylindrical pressure hull made of cylindrical beams (reinforcement rings) positioned 500 mm (19.69 in) apart and to which were riveted multiple steel plates positioned in a brick layer fashion (each plate tended to overlap the other half of the adjacent plates). Plates were made of nickel steel (3% nickel) with a breaking point of 60 kg/mm2 (853.4 psi), and an enervating point of 42 kg/mm2 (597.4 psi). Plates were 20 mm (0.7874 in) thick around midship and 13 mm (0.5118in) thick toward the extremity. The following class, the Pisani, had the rings positioned 600 mm (23.62 in) apart and the steel plates were reduced to 18.5 mm (0.7283 in) and 15.5 mm (0.6102 in)

The forward and aft sections were tapered so that the internal circumference of the supporting beams was larger in the central compartments than the extreme ones. Each plate was secured by a double row of rivets, and an extra plate was installed inside and outside of the riveted area.

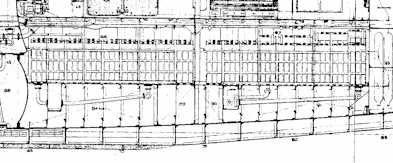

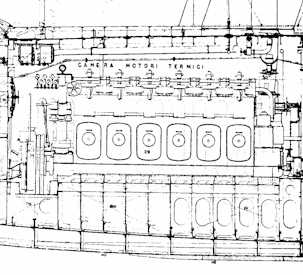

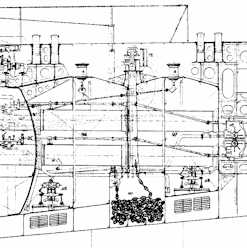

The entire pressure hull was divided into six primary compartments. Starting aft, the first compartment was the aft torpedo room which also included the electric motors, followed by the diesel engine rooms, the control room, the officer and first battery holds, the N.C.O.s quarters and second battery hold, and finally the forward torpedo room. Above the control room there was a smaller chamber (conning tower) made of diamagnetic steel. The two periscope sleeves were also considered parts of the pressure hull and the periscope wells protruded into the resistant ballast tank.

A watertight bulkhead capable of withstanding water pressures up to 40 atmospheres (853.4 psi) separated each compartment, excluding the two battery holds which were divided by a bulkhead resisting only 10 atmospheres (213.3 psi). The small water resistant chamber in the conning tower, as already mentioned, was made of diamagnetic steel, 25% nickel-based steel, thus allowing for operation of a magnetic compass and or radio equipment.

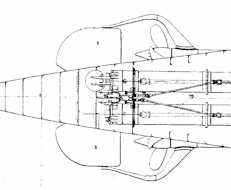

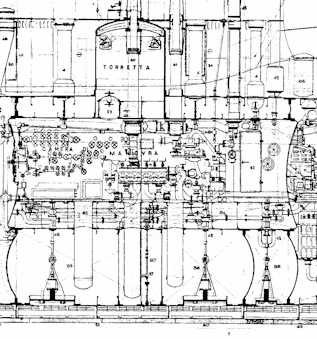

Drawings

Aft Planes

Battery hold

Diesel Engine

Electric motors

Deck gun

Crew quarters

Rudder

Aft tanks

Forward tanks

The main and crash tanks

Torpedo tubes

Propulsion

Diesel Engines

The “Pisani” class was powered by two Franco Tosi “K 6” six cylinder diesel engines capable of producing 1,350 HP. These were four-stroke motors with a primary crankshaft to which were connected the pistons; they could not be reversed (they only rotated one way). The engines were directly connected to a four-stage air compressor which produced air at a pressure of 70 Kg/cm2 m (995.6 psi) and which was also used (in reverse) to start the engines. The “Bandiera” and the “Squalo”were equipped with the new FIAT Q 426, a six-cylinder, two-stroke reversible 1,500 HP diesel engine. The two power plants did not directly effect the surface speed of the boats, but rather their endurance.

The three classes had almost similar performances with the “Pisani” rated at 15 knots, and the “Bandiera” and “Squalo” at 15.1 knots. With continuous use and the general aging of the boats, these values became hardly achievable, especially toward the end of their operational lives. On surface navigation, the engines were connected to the primary axels via a clutch joint, while the axels were connected to the propeller shafts by a geared joint. The geared joints could be disconnected from the propeller shaft and connected to the electric motors, thus turning them into dynamos for the production of direct current. While submerged, the clutch joints were fully disengaged. The two diesel engines received their supply of fresh air from an intake place above deck within the conning tower. The intake was protected by a large valve, which, while the boat was submerged, was sealed.

Electric Motors

On the “Pisani” the two electric motors (double coaxial armature winding) were produced by C.G.E. (Compagnia General Elettricità, Milan) and capable of producing up to 550 HP (410.1 Kw) each. The “Bandiera” were fitted with motors produced by Savigliano, while the “Squalo” received motors produced by C.R.D.A.

The motors on the “Pisani” were powered by direct current and could be supplied with 55, 110 or 220 volts. Each motor could be run at full speed (550 HP) for one hour, at 416 HP for three hours and at 66 HP in continuous motion. The Savigliano installed on the “Bandiera” could produce 650 HP each; those on the “Squalo” were also capable of 650 HP (522 Kw). The difference between the various power plant solutions allowed for various endurance at maximum speed; the “Pisani” and the “Bandiera” were capable of 8.8 miles at 8.2 knots, while the “Squalo” was only capable of navigating 7 miles at 8 knots.

Batteries

On the “Pisani”, “Bandiera” and :Squalo” there were two 56 cell storage batteries; later Bernardis had them increased to 132. On the “Pisani”, each cell was of the type 30 M.A.S. 870-5 produced by the SGIAE of Melzo (near Milan) and weighed 750 kg (1653 lb) The total weight of all cells was 84 tons (92.59 short tons). The batteries could deliver 5,150 amps in one hour, 7,500 amps in three (2,500 amps/hour), and 11,500 amps in twenty hours (575 amps/hour).

This configuration was identical to the “Mameli”, a class designed by Cavallini. This configuration was altered on the “Bandiera” and these boats were fitted with 112 Hensemberger R.M 865/28, batteries these with slightly different performaces (5,200 amps for one, 7,680 for 3 hours, 10,000 for10 hours and 11,000 for 20 hours). The “squalo” received batteries with far less performance; 4,270 amps for one, 6,380 for 3 hours, 8,400 for10 hours and 9,350 for 20 hours

Air Systems

The compressed air system was one of the most important systems on the submarine. It was used to blow the ballast tanks, fire torpedoes, and to start the main engines. Without a functional air system the submarine became inoperable. Docking facilities were usually provided with the necessary high-pressure air supply so that the submarine would not have to produce its own. Air tanks tended to accumulate condensed moisture (water), thus they were regularly drained for maintenance.

On the Bernardis the primary air compressor was installed in the compartment forward of the control room. It was build by San Giorgio and capable of pressurizing air up to 200 kg.cm2 (2845 psi). The compressors were powered by electric motor. There were also two super compressors, also built by San Giorgio, capable of boosting air pressure from about 70 to 200 kg.cm2 (995 to 2845 psi). This system received air from the two compressors built into the diesel engines and air was stored into tanks with a total capacity of 6,202 liters (219 ft3).

These compressors could only be used when the submarine had at least the conning tower out of the water so that the hatch could be open to supply external air. There were also two low-pressure blowers type Reavel-Cerpelli (less than 1.7 atmospheres) capable of 30 m3. The blowers shared the same electric motors as the asset pumps, each capable of moving about 60 tons of water per hour. In case of emergency, the pumps used to launch torpedoes, each capable of about 30 tons per hours, could also be used to move ballast water. The boats were also equipped with emergency pumps driven by low-pressure air or manpower. These hand-operated pumps were capable of about 120 liters per hour (4.238 ft3/h)

Air Filtering System

The Bernardis were equipped with an air regeneration system for the removal of CO2 (Carbon Monoxide). There were also oxygen tanks loaded which were used to oxygenate the depleted air while submerged. The submarine was equipped with external hookups so that, in case of malfunction, a support ship could blow the ballast tank and also provide breathable air.

Crew Quarters

On the early Bernardis the officer’s area was arranged with four bunks, which would turn into two sofas, much like on Italian train cars, and a private cabin for the captain. The crew was divided between the two torpedo rooms, N.O.C. aft and sailors forward.

Galley

There were two galleys, one powered by electricity and located in the forward torpedo room, and one burning diesel oil and located within the conning tower.

Heads

There were three heads inside the submarine, and two inside the conning tower. Naturally, the galley and latrines inside the conning tower could only be used while on the surface.

Fresh Water

The “Pisani” had a total reserve of about 15 m3 (529.7 ft3) of fresh water, later reduced to 11.246 m3 (397.1 ft3) on the “Bandiera”. From the “Bandiera” on, these boat received an electric distillatory device type Kirkaldy capable of producing about 600 liters (21.19 ft3) of distilled water every 24 hours.

Refrigeration

Oddly enough, on the “Pisani” the refrigerator for the production of ice and the preservation of fresh foodstuff was located in the aft torpedo room, and was made by Frigidaire. On the “Bandiera” it was replaced by a new machine produced by Glacia.

Crew

The “Pisani” had a crew of 5 officers and 44 enlisted. The “Bandiera” and the “Squalo” had 5 officers and 47 enlisted. On later Bernardis, the crew was increased to 57.

Safety Systems

Between the torpedo rooms and the internal compartments, the engineers had placed two Gerolami-Arata lifts. These devices consisted of a sealed chamber, which would float to the surface by buoyancy and could then be retrieved by a tether connected to the bottom of it and secured to a winch. Each time the chamber was released it could take one crewmember to the surface without incurring any of the dangers caused by exposing the human body to the high water pressure of the depths. Due to the presence of this device, the bulkhead between the torpedo rooms and the inner compartments was equipped with two hatches.

Navigation

The Bernardis were equipped with a gyrocompass with repeaters installed in various compartments. There was also a magnetic compass. The gyrocompass received its directive from a high speed spinning gyroscope driven by electric motors. Its directive action is based on the mechanical laws governing the dynamics of rotating bodies. When any object is spinning rapidly it tends to keep its axis pointed in the same direction. The gyrocompass consists of a spinning gyroscope, made north-seeking by placing a weight below the axis, which is mounted in gimbals so that the movements of the submarine do not effect its position. A dial mechanically connected to the gyrocompass has the points of the mariner’s compass marked on it and indicates the submarine’s true course.

Radio

On the “Pisani” the radio equipment consisted of a 3 kW short-wave radio set (utilizing tubes). The antenna consisted of a stay and cables running forward and aft almost the full length of the boat. The radio room was installed in the control room.

Hydrophones

There was a hydrophone system connected to transmitters mounted on the hull.

General announcing system

All “Bernardis” were equipped with an announcing system. Each compartment could communicate with a central station located in the control room via a speaker microphone system.

Alarm system

The “Bernardis” were equipped with a klaxon operated from the control room. Upon sounding the alarm, all hatches would be secured and the engineers would commence the diving procedures securing the diesel engines’ intake and exhaust valves.

Telephone call system

The “Bernardis” were equipped with two buoys situated on deck and attached to a retrieval system. If necessary, the buoys could be released and floated to the surface, giving surface units a telephone connection to the submarine.

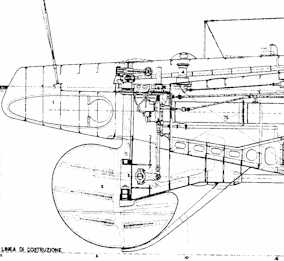

Periscope

There were two periscopes produced by the firm Galileo of Florence. The forward one was used to attack, while the aft one was used for exploration. Both periscopes were accessible from the control room, rotated by hand, but were lifted and retracted electrically.

The Fratelli Bandiera in the foreground and the Victor Pisani in the background in 1943. Note how the periscopes of the Pisani were considerably reduced in size.

(Photo courtesy Erminio Bagnasco and Achille Rastelli)

Typical of Italian submarines, the periscope sleeves extended considerably from the conning tower and were quite visible from a distance. During the war, the sleeves were reduced in size and picture of the Delfino shows a conning tower almost as small as the one used by German submarines.

Controls

When the “Bernardis” were on the surface, they operated like any other boat demonstrating mediocre seaworthiness due to the known problems with the design of the hull. Maintaining the various ballast tanks full of air provided buoyancy.

Rudder

The rudder (semi-compensated) was controlled electrically from the control room, or manually for the aft torpedo room. On the “Pisani” the rudder had a total surface of 6.445 m3 (69.37 ft2).

Diving Planes

As standard on most submarines, the “Bernardis” were equipped with two sets of diving planes. The forward planes were collapsible (folded upward) for surface navigation and were placed above the waterline; their total surface was 4.796 m2 (on the “Pisani”). The aft planes were fixed and placed below the waterline in line with the two propellers and their total surface was the same 4.796 m2 (51.62 ft2). The forward planes were used to control depth, while the aft ones were used to control the angle of the boat. The planes were controlled electrically from the control room, but could also be manually operated from the torpedo rooms.

Anchors

The “Bernardis” were equipped with an anchor placed portside forward.

Weapons

Torpedoes

All “Bernardis” excluding the “Pisani” were fitted with four torpedo tubes aft and four forward. The “Pisani” had only two tubes aft. All tubes were loaded before leaving port and two extra torpedoes were stowed in each compartment giving the “Pisani” a total of 10 torpedoes, while all other boats had 12. Torpedoes were loaded through a special hatch and the operation was very laborious. Once at sea, torpedoes could be removed from the tubes for limited maintenance (fuel topping).

Range, speed and direction of the weapons could be configured while they were inserted in the tubes. The tubes could take a variety of 21′ (533 mm) torpedoes produced both by Whitehead and “Silurificio Italiano”. Similar to the Royal Navy, the Regia Marina did not experience the kind of massive torpedo failure which plagued the U.S. Navy and the Kriegsmarine.

Smaller weapons

Each boat was equipped with a small armory containing rifles and side arms.

Deck Guns

The early “Bernardis” were fitted with a 4″ (102) mm deck gun caliber 35 produced by O.T.O. (Model 1931, 35 and 38). These guns had a maximum range of 14,500 meters, but the practical range, due to the simplicity of the optical range-finder, was much lower.

The 102 mm gun on the Bandiera

The “Pisani” carried a total of 168 shells: 22 kg Ap or smaller 13.8 kg conventional shells. The “Bandiera” and “Squalo” had a reserve of 150 shells. The muzzle velocity, originally at around 730 m/s, was later increased to 840 m/s. A well-trained gunnery team could fire eight shells per minute. Shells were loaded from the stowage area below onto the main compartment and from there pushed up to the deck through a tube. The gunners also had access to a ready storage area built into the conning tower and secured by a watertight hatch.

Machine Guns

All “Bernardis” were equipped with the famous Breda Model 1931 13.2 mm anti-aircraft machine gun. These guns were mounted on a single support. The guns were installed on a retractable mount which would recede into a water-tight tube protected by a small hatch. Upon emerging, the gunners had to simply release the hatch, lift the guns out of the enclosure, install a clip and fire. Each clip contained 30 rounds and the gun could fire up to 400 rounds per minute at a range of 2,000 meters. These boats had a reserve of 3,000 rounds. As with all Italian submarines, toward the end of the conflict it was discovered that the 13.2 mm guns were insufficient in downing large American bombers protected by a thick armor.